UK preview of VISI 18

Vero Software, a leading provider of CAD/CAM/CAE solutions for the tooling industry, will present the first viewing of its flagship product VISI 18 during MACH 2010 (Hall 5, 5495). Due for a summer release, VISI 18 is another substantial release with many new features in all areas of the product with a continued focus on tool design and manufacture.

VISI Modelling is the base platform for all VISI products and version 18 delivers an updated GUI with graphic sliders that allow the user to dynamically interact with the working area to push or pull features and apply other system commands. One major CAD development is the introduction of geometry deformation tools that provide a technical leap forward and deliver exciting new features such as complex spring back deformation, draft application and organic shape editing. These new features will greatly benefit existing users who have to adapt customer data and also support more aesthetic markets such as product design or cosmetics.

VISI Machining has been updated with a number of tools to further enhance the automated Compass Technology including a new method to manage the smallest distance between two or more sides of a geometric feature. This distance can be used to identify the smallest tool diameter for a pocket or define other machining variables. Other CAM developments include improved 3D constant step over, an improved 3D combi-finishing routine, updated rapid management and improved drilling cycles with a new wizard application for the construction of complex multi-operation cycles.

Sheet metal development has been significantly improved with dynamic animation of the forming process and a batch procedure for developing multiple components simultaneously with a report for each piece. When working with imported geometry, fillet radii is often missing but required for blank development or step-by-step unfolding. VISI 18 introduces a new tool to automatically apply blend radii to inner and outer sharp edges. Other developments include new options for body interference checking and also a new tool to automatically create the hard inserts for die plates and apply relief holes to the corners. Finally, Vero have extended their partnership with CADENAS and have integrated PartSolutions V9 into the tooling suite, VISI Mould and VISI Progress.

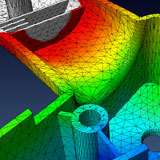

VISI 18 completes the full integration of VISI Flow and now the plastic injection analysis and simulation can be launched and calculated from directly within VISI, eliminating the need of model preparation for analysis. Importantly, the calculation results are also visible within the same CAD environment providing the perfect toolset for comparing the original model against the warped prediction data after the moulding process. VISI Flow also includes the ability to work with shell models and introduces a virtual resin laboratory that allows users to create and test different kinds of resin grades. The 'Virtual Laboratory' is based on intelligence included within the VISI Flow material database and works by following an interactive iterated approximation. The application is able to put together data coming from different databases and different grades by following a wizard based on user instructions such as polymer family, density and MFI.

Also being previewed at MACH 2010 will be the first release of VISI PEPS-Wire. After the acquisition of Camtek Limited, VISI PEPS-Wire represents over 2 years of development and combines the class-leading technology of PEPS Wire with Vero’s Parasolid based geometry-engine. The first release of VISI PEPS-Wire will introduce automated 2 and 4 axis feature recognition, dramatically improved geometry tools and combined Milling and Wire EDM cutting strategies.

Gerard O'Driscoll, R&D Director for Vero explains, "Using VISI as a development platform will allow PEPS customers to introduce further productivity tools such as modelling, progression tool design, mould tool design, and multi-axis machining. Whilst there will be a new user-interface to learn, the machining technology and core PEPS product will still be very familiar to existing users."