VISI with Caliberg

Since the early 1960s, aerosols have been well established in the cosmetics industry and over the years aerosols containing deodorant, perfume, insecticide, polish and paint have all found their way into our homes. The next time you use one of these aerosols, look at the plastic spray diffuser - it may have been made by Caliberg in Italy.

Caliberg was founded in 1959 in Bergamo, northern Italy, producing progressive press tools and dies. By the early seventies, the rapid and sweeping development of new plastic materials created new opportunities and the company developed a talent for creating original mould designs and producing high precision plastic parts in large quantities.

"We have always worked to develop relationships with companies such as Vero who are strong in their particular sector."

Tommaso Maggi, Owner

As part of their strategic plan to continually expand their business, Caliberg realised the necessity to invest in avant-garde CAD/CAM software and chose to invest in the latest technology provided by Vero Software Plc. Caliberg currently run five work-stations with VISI Mould, VISI Wire and VISI Machining 3D for their design and production departments specialising in multi-cavity moulds for small components (e.g. aerosol valves and pumps, medical devices and disposable shavers).

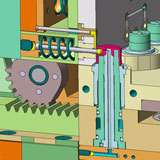

The pneumatic and electronic mechanism of the aerosol valve mould which simultaneously moulds and assembles two plastic components was designed and created using VISI and has been successfully patented by Caliberg.

Today Caliberg – led by father and son, Andrea and Tomaso Maggi – employ thirty highly skilled people and Tommaso comments “Human resources are the true wealth of our delicate and complex job. We use our resources to guarantee that we truly excel in our areas of specialisation; project design, engineering and manufacturing of moulds. We have always worked to develop relationships with other companies – such as Vero – who are strong in their particular sectors. As a result values like participation, awareness and flexibility become benefits for our clients who can rely on the professional expertise of the whole team

As well as being experts in multi-cavity mould design, Caliberg also specialise in the design of multiple solutions including stack moulds to obtain the maximum number of parts from a single moulding machine, floating island moulds to control tight tolerances when perfectly matching two halves of a mould, hot runner injection and runnerless injection moulds. Within this specialised and often complex arena, Caliberg are considered experts in the field of multi-material and multi-component simultaneous moulding, assembly and testing for the production of aerosol valves with a critical tolerance of +/- 0,005mm. One of the applications in this field won the award ‘The mould of the year’ at the Eurostampi exhibition.

Vero Software Plc is represented in over 40 countries by more than 80 distributors and, in addition to its extensive dealer network, has its own direct sales operations in the UK, France, Italy, USA, Japan, China and Canada.

About The Company:

Name:CalibergWeb:www.caliberg.it

Comments:

"We have always worked to develop relationships with companies such as Vero who are strong in their particular sector."

Tommaso Maggi

Owner